2022-09-06

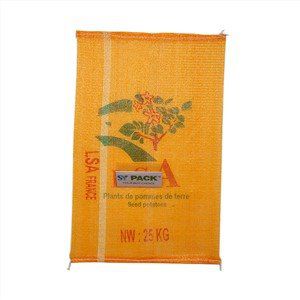

The net bag is made by the net bag manufacturer with polypropylene and polyethylene resin as the main raw materials and a small amount of auxiliary materials. After mixing, it is melted by the extruder. The extruded plastic film is cut into filaments and stretched at a temperature lower than the resin melting temperature. The flat filaments with high strength and low elongation are made by molecular orientation and heat setting, and then are wound, woven, cut and sewn.

According to the results of continuous sampling inspection of net bag products in recent years, it is found that the unqualified items of net bag products are mainly concentrated on the tensile load items. The tensile load items of net bags are an important indicator, and the unqualified items directly affect the overall quality of net bags. The appearance of the net bag shall meet the following requirements. It is not allowed to have 3 broken wires at the same place on the cloth surface. The suture requirements are not allowed to have the needle off, broken wires, and the folded parts not sewn. These problems also directly affect the tensile load index.

In the production process of net bag manufacturers, the improper selection of raw material ratio, flat wire quality, unit area quality and poor weaving process control will directly affect the tensile load of plastic woven bags.

Previous: Factors affecting the quality of mesh bag suture

Next: Null